Hansung Food Manufacturing Process

According to the food safety management certification standard HACCP, each process is managed with emphasis so as to prevent harmful substances from being mixed into the food products or food product contamination in all process of raw material management, manufacturing, processing, cooking, and distribution.

All staff and employees of Hansung Food have been acknowledged for the sanitary and safe food manufacturing management abilities from an international accreditation agency.

1. Cabbage warehousing

cultivated under contract at the

origin through strict inspection

2. Put cabbage

using robot palletizer

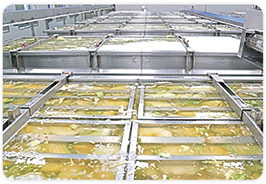

3. Pickling

on the season

4. Cleaning

Vortex one-stage washing

5. Foreign substance sorting

after cleaning

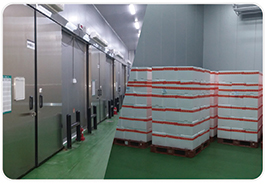

6. Low temperature dewatering

temperature refrigeration

7. Seasoning mix

ingredients and condiments

8. Stuffing

9. Metal detection and packaging

10. ferment

11. Shipment